Laser and plasma cutting machines produce some of the most dangerous particulates in modern manufacturing—microscopic metal fumes, vaporized alloys, smoke plumes, and ultra-fine airborne contaminants. These particles, once airborne, can spread rapidly, infiltrate equipment, weaken electrical components, and pose serious respiratory threats.

Across advanced manufacturing facilities in the Philippines, NuPon Technology Phils. Corp. delivers powerful, certified dust collection systems engineered to handle the intense particulate output of laser and plasma cutting operations. Our systems stabilize airflow, protect machinery, and maintain a safer, cleaner cutting environment.

Practical Scenarios Where This Solution Becomes Essential

- Ultra-fine smoke and metal fumes accumulate faster than standard ventilation can handle

High-temperature cutting processes require specialized extraction to protect workers and optics. - Cutting accuracy is affected by airborne fumes and particulate backflow

Stable suction maintains a clean cutting environment and consistent beam output. - Equipment electronics become contaminated by fine metallic vapors

Robust filtration prevents fume infiltration and prolongs machine reliability in Philippine production lines.

Engineered Dust Collection Solutions for Laser & Plasma Cutting

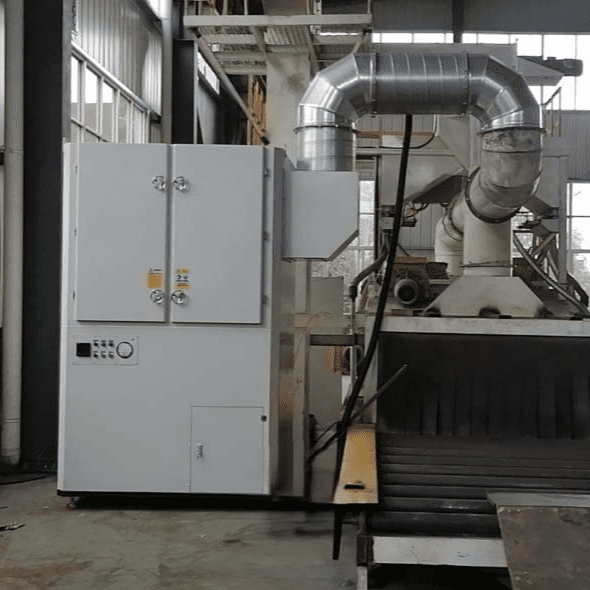

💠 High-Pressure Fume Extraction System

Industrial Dust Collector DJS1100/DJS1500

A high-airflow, constant-pressure system designed for large laser and plasma cutting machines. Features massive HEPA filtration, variable frequency control, and precise suction for continuous removal of metallic fumes and smoke.

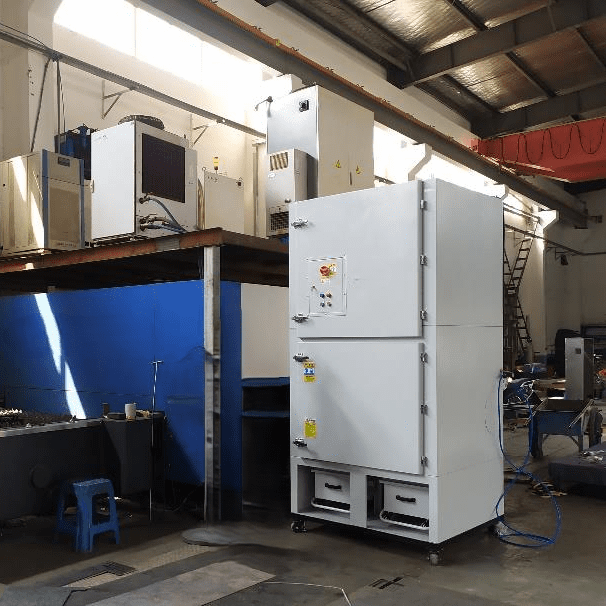

💠 Flame-Retardant Plasma Cutting Dust Control Unit

Industrial Dust Collector DJS550/DJS750

Equipped with PTFE-membrane flame-retardant HEPA filters, this unit handles the intense temperature and spark-heavy environment of plasma cutting. Its deflector inlet protects filters from high-impact particles.

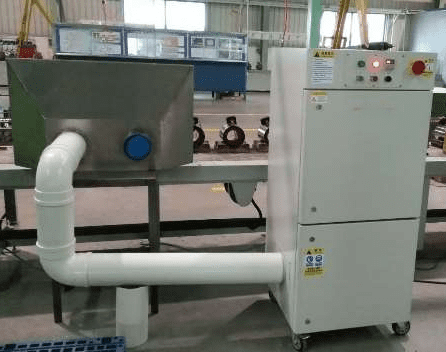

💠 Localized Laser Cutting Smoke Capture System

Industrial Dust Collector AJS220

Ideal for smaller laser cutters, engraving machines, marking stations, and precision cutting setups. Quiet, efficient, and built with durable PTFE HEPA cartridges for sub-micron particle filtration.

Where These Solutions Add Value in Cutting Operations

- CNC laser cutting facilities

- Plasma cutting stations

- Robotic cutting lines

- Fabrication & metalworking centers

- Stainless steel, aluminum, and alloy cutting lines

- Sign-making and precision cutting workshops

Quick Comparison Table

| Solution | Key Benefit | Usage Area |

|---|---|---|

| High-Pressure Fume Extraction System | Maintains strong suction & stable airflow for large cutting tables | Large laser/plasma machines |

| Flame-Retardant Cutting Dust Control Unit | PTFE flame-retardant filters endure high heat & sparks | Heavy-duty plasma cutting lines |

| Localized Laser Cutting Smoke Capture System | Precision suction for fine fumes & engraving smoke | Small laser cutters, marking setups |

| PTFE Membrane HEPA Filtration System | Filters ultra-fine 0.1–0.3µm metallic fumes | High-purity cutting environments |

| Automatic Pulse-Jet Cleaning System | Prevents filter clogging during long cutting cycles | All cutting operations |

Sharper Cuts, Cleaner Air, Safer Operations

Laser and plasma cutting generate high volumes of toxic, ultra-fine fumes. Without proper filtration, these contaminants damage optics, clog machine pathways, and pose major respiratory hazards.

NuPon’s certified dust collection systems ensure:

- cleaner and clearer cutting visibility

- longer machine lifespan

- stable production and reduced downtime

- compliance with industrial air-quality requirements

- safer worker breathing zones

As a Philippine-based provider, NuPon Technology Phils. Corp. elevates local cutting facilities with engineered airflow solutions that meet global manufacturing standards.

Upgrade Your Cutting Line with NuPon Dust Collection Systems

Our cutting-specific solutions are engineered to handle extreme workloads, harsh temperatures, and continuous production cycles.