Industrial workshops across the Philippines—machine shops, fabrication floors, assembly lines, welding bays, and mixed-process environments—are constantly exposed to airborne contaminants. Grinding dust, welding fumes, laser particulates, sanding residue, metallic fragments, and general workshop debris can compromise worker safety, degrade product quality, and damage sensitive equipment.

As a proudly Philippine-based engineering provider, NuPon Technology Phils. Corp. delivers certified, heavy-duty dust collection systems designed specifically for multi-process industrial workshops. Our solutions stabilize air quality, reduce contamination, and protect operators in high-activity production spaces.

Practical Scenarios Where This Solution Becomes Essential

- Multiple processes generate overlapping dust streams throughout the workshop

Unified extraction ensures stable air quality across diverse work areas. - Tooling and machines show premature wear caused by particulate exposure

Effective filtration reduces downtime and maintenance costs. - Production zones fail to maintain safe indoor air quality during peak operations

Facilities rely on industrial-grade collectors to comply with workplace standards in the Philippines.

Engineered Dust Collection Solutions for Industrial Workshops

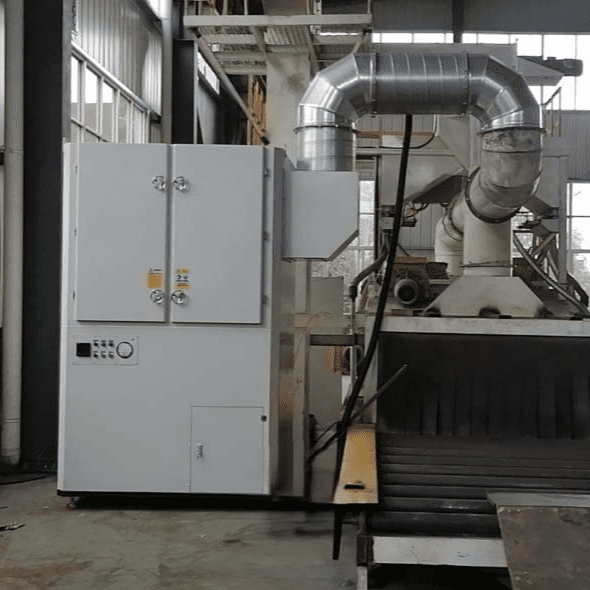

💠 Centralized Multi-Process Workshop Dust Extraction System

Industrial Dust Collector DJS1100/DJS1500

Built for large workshops with multiple dust-generating zones, this system delivers high air volume, constant pressure control, and massive HEPA filtration area—ensuring continuous clean airflow across the entire shop floor.

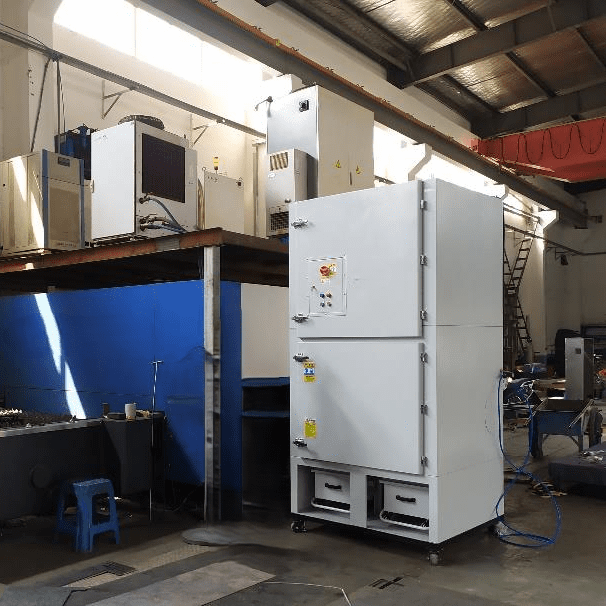

💠 Workshop Heavy-Duty Fume & Dust Control Unit

Industrial Dust Collector DJS550/DJS750

Designed for mixed environments involving welding, grinding, cutting, and polishing. Features flame-retardant PTFE HEPA filters, high static pressure, and dust-impact inlet protection for durability in dynamic workshop setups.

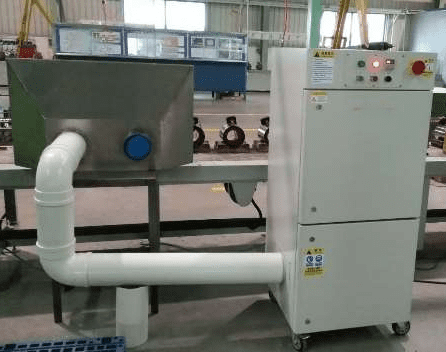

💠 Mobile Workstation Dust Capture System

Industrial Dust Collector AJS220

A highly efficient, compact unit ideal for individual workstations—CNC setups, grinders, polishing stations, or bench-level tasks. Low noise, strong suction, and easy filter replacement make it the perfect flexible workshop solution.

Where These Solutions Add Value in Industrial Workshops

- Machine & metal fabrication workshops

- Assembly & production lines

- Automotive maintenance & repair bays

- Welding + grinding hybrid stations

- Laser & plasma cutting zones

- Wood-metal mixed processing workshops

- Custom fabrication and prototyping facilities

Quick Comparison Table

| Solution | Key Benefit | Usage Area |

|---|---|---|

| Centralized Multi-Process Workshop Dust Extraction System | Covers multiple zones with high airflow & constant pressure | Large workshops, fabrication floors |

| Heavy-Duty Fume & Dust Control Unit | Flame-retardant HEPA filters + dust-impact protection | Welding, grinding & mixed-process areas |

| Mobile Workstation Dust Capture System | Compact, efficient, localized dust removal | CNC stations, benches, small work areas |

| PTFE Membrane HEPA Filtration System | Captures sub-micron workshop dust (0.1–0.3µm) | High-precision or clean-critical zones |

| Automatic Pulse-Jet Cleaning System | Maintains filter efficiency during non-stop operations | All multi-process workshop setups |

Clean, Safe, and Efficient Workshop Performance

Industrial workshops demand continuous filtration, reliable airflow stability, and rugged equipment capable of functioning in high-activity environments. NuPon’s certified systems ensure:

- Cleaner working conditions

- Safer operator breathing zones

- Lower equipment contamination

- Reduced fire hazards

- Stable production and compliance

As a Philippine-based provider, NuPon Technology Phils. Corp. is committed to elevating the safety and efficiency of local workshops through precision-engineered dust collection technology.

Upgrade Your Industrial Workshop with NuPon Dust Solutions

From light-duty workbenches to full-scale production floors, our engineered systems deliver unmatched performance and air quality control.