Woodworking facilities—carpentry shops, furniture factories, millwork operations, and CNC routing centers—produce enormous volumes of airborne sawdust, fine wood particles, chips, and fibrous contaminants. Without proper dust extraction, these particulates accumulate rapidly, creating hazards that affect worker safety, machine performance, and product quality.

Across carpentry and manufacturing hubs in the Philippines, NuPon Technology Phils. Corp. delivers certified, high-performance dust collection systems engineered to manage the full range of airborne wood particulates. From sanding dust to CNC routing debris, our systems maintain safe airflow, cleaner workspaces, and consistent production output.

Practical Scenarios Where This Solution Becomes Essential

- Sawdust accumulates rapidly and creates visibility and fire hazards

Woodworking shops require strong extraction to maintain safe daily operations. - Fine sanding dust infiltrates CNC machines and reduces performance

Consistent filtration extends machine service life and maintains precision. - Airborne wood particulates exceed acceptable indoor levels during peak production

Facilities rely on dust collectors to meet workplace safety expectations in the Philippines.

Engineered Dust Collection Solutions for Woodworking Systems

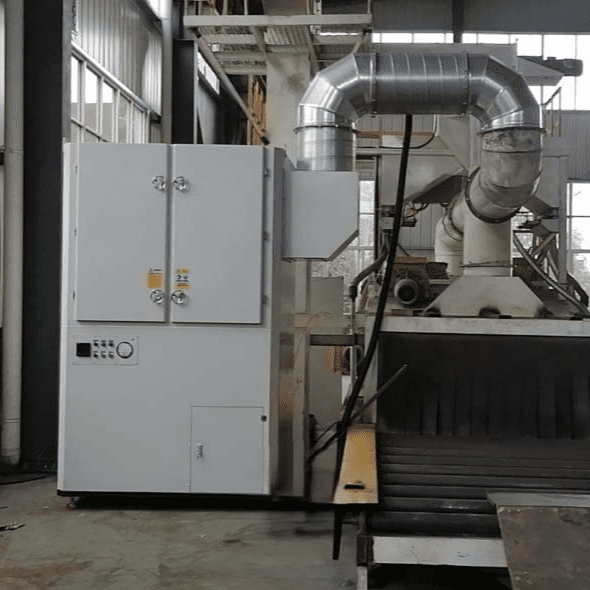

💠 High-Volume Woodshop Dust Extraction System

Industrial Dust Collector DJS1100/DJS1500

Built for robotic welding lines, large welding halls, and continuous welding operations. Offers constant-pressure airflow, large HEPA filtration area, and high-volume suction ideal for thick weld smoke and high-temperature metal fumes.

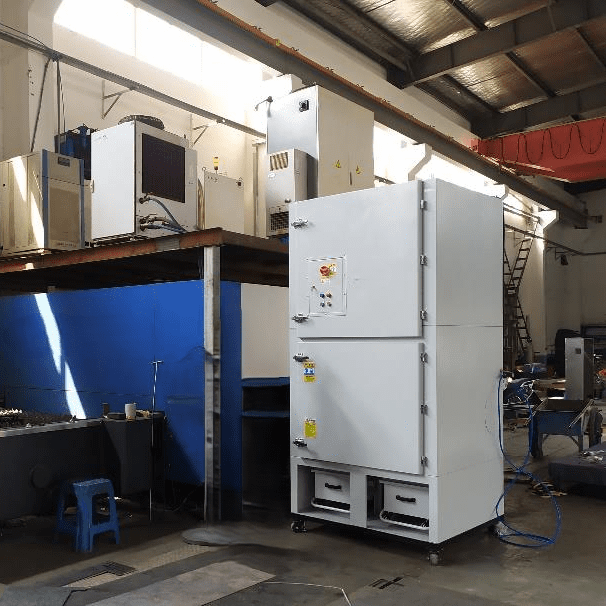

💠 Multi-Stage Wood Dust & Chip Filtration Unit

Industrial Dust Collector DJS550/DJS750

Equipped with PTFE flame-retardant HEPA filters, this unit handles sanding dust, routing debris, planer chips, and multi-process woodshop contaminants with high durability and stable performance.

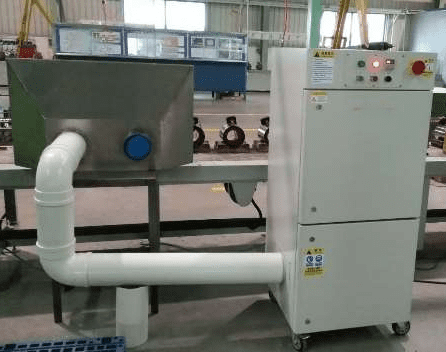

💠 Compact Bench & CNC Woodworking Dust Collector

Industrial Dust Collector AJS220

Ideal for smaller woodshops and individual machines such as sanders, routers, carving stations, and trimming benches. Quiet, efficient, and built with easy-to-service HEPA cartridges.

Where These Solutions Add Value in Woodworking Operations

- Wood sanding lines

- CNC router and carving stations

- Furniture manufacturing plants

- Cabinet and millwork shops

- Wood turning & carving facilities

- Planer, jointer, and thicknesser stations

- Trim, buffing, and finishing rooms

Quick Comparison Table

| Solution | Key Benefit | Usage Area |

|---|---|---|

| High-Volume Woodshop Dust Extraction System | Handles large debris + fine dust with stable airflow | Furniture factories, CNC hubs |

| Multi-Stage Wood Dust & Chip Filtration Unit | Flame-retardant HEPA filters, strong impact protection | Mixed-process woodworking shops |

| Compact Bench & CNC Woodworking Dust Collector | Space-saving localized dust removal | Small shops, single machines |

| PTFE Membrane HEPA Filtration System | Captures ultra-fine 0.1–0.3µm wood dust | Sanding and fine woodworking zones |

| Automatic Pulse-Jet Cleaning System | Maintains suction throughout heavy dust cycles | High-duty woodworking operations |

Cleaner Woodshops. Safer Tools. Better Output.

Wood dust is one of the most explosive, health-hazardous, and equipment-damaging particulates in the industry. NuPon’s engineered systems provide:

- safer breathing zones

- reduced fire risks

- extended cutter and tool lifespan

- stable CNC performance

- cleaner finishing and coating results

- more efficient shop operations

As a proudly Philippine-based engineering provider, NuPon Technology Phils. Corp. supports local woodworking businesses with industrial-grade dust extraction designed for precision and durability.

Upgrade Your Woodshop with Professional Dust Collection Systems

From artisan carpentry shops to full-scale furniture factories, NuPon delivers powerful, reliable dust solutions that elevate both safety and productivity.