Battery cell production—whether for lithium-ion, nickel-based, or advanced energy storage systems—demands an environment of absolute precision. Micro-powders, conductive particulates, chemical dust, and fine contaminants produced during mixing, coating, tab welding, electrode processing, and cell assembly pose significant risks to product quality, worker safety, and equipment integrity.

Across the Philippines’ rapidly growing energy manufacturing sector, NuPon Technology Phils. Corp. provides certified industrial dust collection systems engineered to support high-purity battery environments. Our technology ensures stable airflow, controlled particulate removal, and continuous protection against cross-contamination in sensitive processing zones.

Practical Scenarios Where This Solution Becomes Essential

- Conductive micro-powders begin affecting the reliability of sensitive battery equipment

High-efficiency filtration protects precision tools used in Philippine battery production. - Contaminants compromise purity levels required for cell assembly

Dust control ensures fewer defects and higher manufacturing consistency. - Airborne particulates exceed acceptable limits in powder-handling or electrode zones

Controlled extraction maintains safe working conditions for operators and engineers.

Engineered Dust Collection Solutions for Battery Manufacturing

💠 High-Purity Battery Production Dust Extraction System

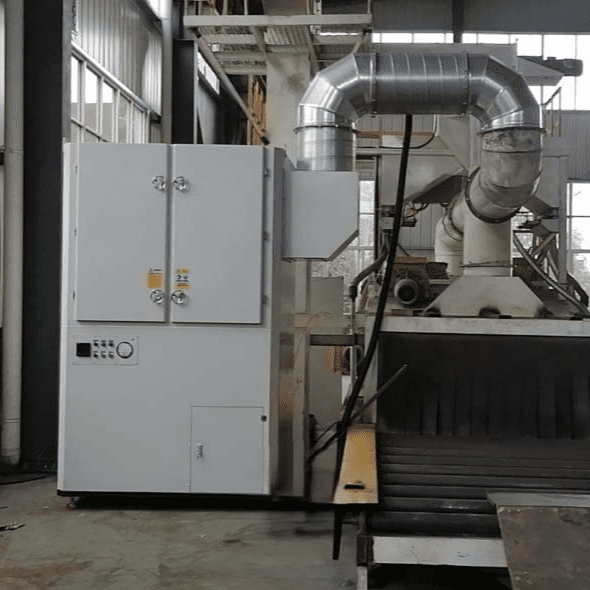

Industrial Dust Collector DJS1100/DJS1500

Delivers constant pressure, large HEPA filtration surface area, and high airflow stability—ideal for electrode punching, tab welding, powder mixing, and large-scale battery assembly rooms requiring continuous particulate control.

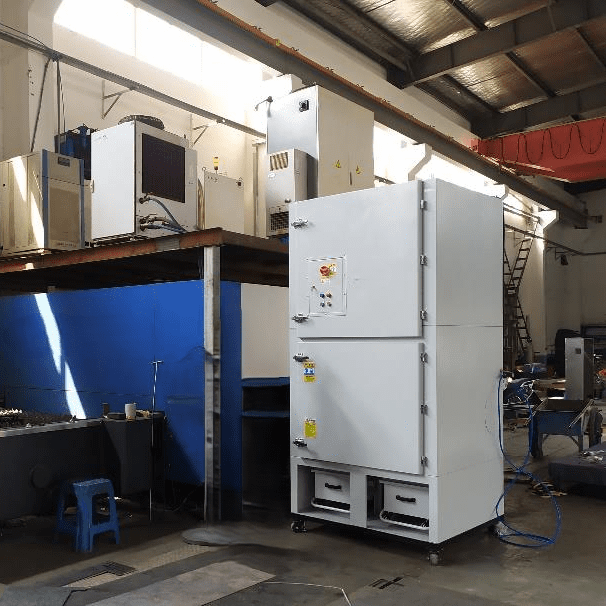

💠 Conductive Powder & Chemical Dust Control Unit

Industrial Dust Collector DJS550/DJS750

Equipped with PTFE flame-retardant HEPA filters and a dust-impact deflector, this system is perfect for capturing charged particulates, carbon dust, metal fines, and process powders during electrode processing and coating preparation.

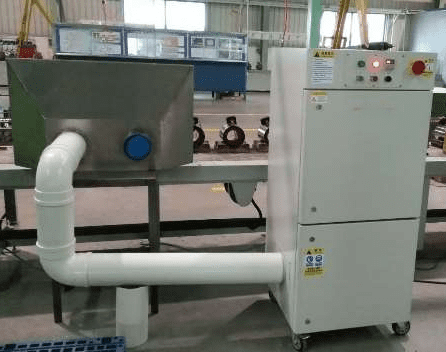

💠 Precision Micro-Particulate Capture System

Industrial Dust Collector AJS220

A compact, efficient solution for bench-level processes such as small cell assembly, powder weighing, laser tab welding, and precision electrode trimming. Features easy-to-replace HEPA cartridges for sub-micron particulate containment.

Where These Solutions Add Value in Battery Cell Production

- Cathode & anode powder mixing

- Electrode cutting, trimming, and punching

- Cell assembly lines

- Tab welding (laser or ultrasonic)

- Coating preparation areas

- Battery R&D laboratories

- Dry room support systems

- EV battery module fabrication

Quick Comparison Table

| Solution | Key Benefit | Usage Area |

|---|---|---|

| High-Purity Battery Dust Extraction System | Stable constant-pressure airflow for critical environments | Mixing rooms, assembly halls |

| Conductive Powder & Chemical Dust Control Unit | Safely captures conductive and fine chemical dust | Electrode processing lines |

| Precision Micro-Particulate Capture System | Superior localized extraction for sensitive processes | R&D labs, small assembly tasks |

| PTFE Membrane HEPA Filtration System | Filters ultra-fine 0.1–0.3µm particles | Clean-critical battery zones |

| Automatic Pulse-Jet Cleaning System | Maintains filter efficiency during powder-heavy cycles | High-volume production areas |

Protect Your Battery Line with Precision Filtration

Battery manufacturing demands exceptional particulate control—especially when dealing with conductive materials that can cause equipment failures, short circuits, or product defects.

NuPon’s engineered systems provide:

- consistent high-purity airflow

- reduced cross-contamination risk

- safer operator conditions

- extended process equipment lifespan

- stable, compliant dust-removal performance

As a trusted Philippine-based engineering provider, NuPon Technology Phils. Corp. supports the nation’s energy sector by delivering world-class dust collection technology designed for next-generation battery production.

Upgrade Your Battery Assembly Environment with NuPon Dust Collection

High-purity manufacturing requires high-precision airflow craftsmanship—NuPon delivers both with industrial reliability.