Powder coating facilities face one of the most demanding air-quality challenges in modern manufacturing. Overspray particles, airborne resin powders, static-charged particulates, and fine contaminants can spread rapidly throughout the workspace—affecting coating quality, compromising curing results, and endangering both workers and sensitive equipment.

Across industrial zones in the Philippines, NuPon Technology Phils. Corp. delivers advanced, certified dust and overspray collection systems engineered to maintain clean, controlled airflow throughout powder coating processes. Our systems capture overspray at the source, stabilize booth airflow, and preserve paint quality across all coating stages.

Practical Scenarios Where This Solution Becomes Essential

- Powder overspray spreads beyond the booth during heavy application cycles

Consistent extraction helps maintain clean work zones. - Curing quality declines due to airborne powder contamination

Effective dust control prevents surface defects and coating inconsistencies. - Operators are exposed to excessive powder particulates during manual spraying

Facilities rely on strong filtration to maintain worker safety and compliance.

Engineered Dust Collection Solutions for Powder Coating Operations

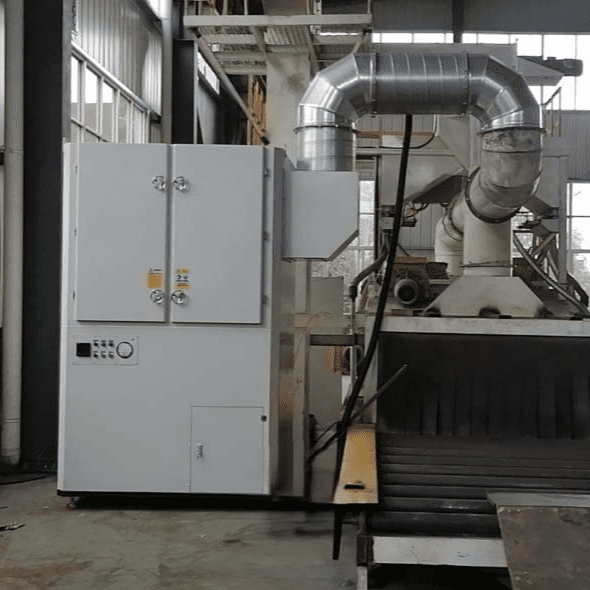

💠 High-Volume Powder Overspray Extraction System

Industrial Dust Collector DJS1100/DJS1500

Built for large powder coating booths and automated coating lines, this system provides constant pressure regulation, massive HEPA filtration surface, and high-volume airflow capable of capturing heavy powder loads and micro-particulates.

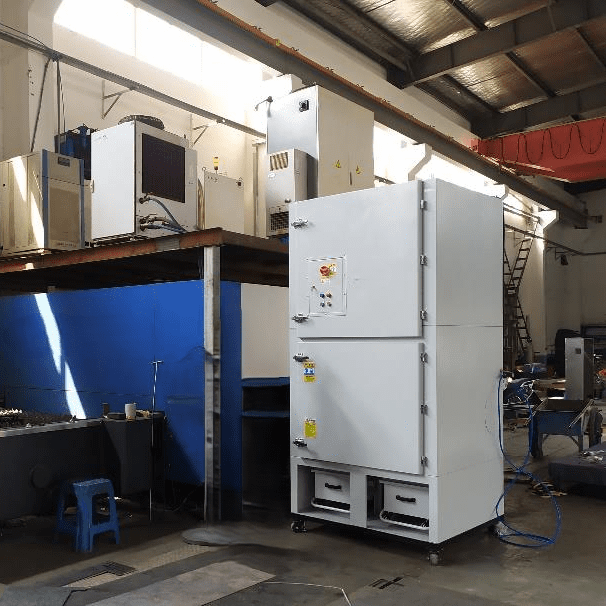

💠 Flame-Retardant Powder Capture Unit

Industrial Dust Collector DJS550/DJS750

Featuring PTFE-membrane flame-retardant HEPA filters, this system is ideal for powder operations that require anti-static protection and reliable overspray management. Its deflector inlet reduces direct impact on filters for longer service life.

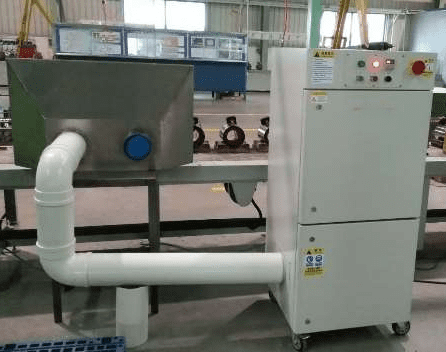

💠 Compact Powder Coating Bench Collection System

Industrial Dust Collector AJS220

Perfect for small-scale or manual powder coating stations. Quiet, powerful, and featuring quick-change HEPA cartridges, this compact system efficiently captures fine powder drift, overspray, and bench-level contaminants.

Where These Solutions Add Value in Powder Coating

- Powder coating booths & spray rooms

- Automotive restoration & repainting centers

- Metal furniture and fabrication factories

- Appliance coating lines

- Aluminum extrusion finishing areas

- Industrial coating workshops

- Small manual coating benches & pre-painting areas

Quick Comparison Table

| Solution | Key Benefit | Usage Area |

|---|---|---|

| High-Volume Powder Overspray Extraction System | Stable airflow + large HEPA area for overspray control | Large powder coating booths |

| Flame-Retardant Powder Capture Unit | Anti-static, flame-retardant PTFE filters | Automated lines, heavy powder applications |

| Compact Powder Coating Bench Collection System | Efficient localized overspray capture | Manual coating benches, small rooms |

| PTFE Membrane HEPA Filtration System | Captures fine 0.1–0.3µm powder particles | High-precision coating operations |

| Automatic Pulse-Jet Cleaning System | Keeps filters clean during powder-heavy cycles | All powder coating environments |

Cleaner Coats, Safer Workspaces, Superior Results

Powder coating demands extremely clean air to ensure uniform finishing and long-lasting results. NuPon’s engineered systems provide:

- Overspray containment

- Reduced product contamination

- Cleaner curing results

- Fire risk reduction

- Optimized booth airflow

- Safer operator working conditions

As a Philippine-based engineering solutions provider, NuPon Technology Phils. Corp. supports local manufacturers with world-class dust collection technology built to enhance coating quality and operational consistency.

Upgrade Your Powder Coating Line with NuPon Dust Extraction Systems

Whether your facility handles manual spraying or full-scale automated coating, NuPon provides the airflow control and filtration strength needed to achieve premium, consistent finishes.