Grinding operations—whether in metalworking, fabrication, machining, or finishing—produce some of the most hazardous airborne particulates in any industrial environment. Fine metallic dust, abrasive residues, and micro-shavings can spread rapidly across the workspace, damaging equipment, contaminating surfaces, and posing serious respiratory risks.

Across manufacturing hubs in the Philippines, NuPon Technology Phils. Corp. provides engineered dust collection systems built to capture grinding dust at the source, stabilize airflow, and maintain safe, compliant working conditions. Our certified solutions are designed for high-demand operations where precision, cleanliness, and worker protection are non-negotiable.

Practical Scenarios Where This Solution Becomes Essential

- Fine metallic dust accumulates rapidly during extended grinding tasks

Workshops need dependable extraction to protect operators and maintain clean air conditions. - Precision grinding equipment experiences performance decline due to dust build-up

Consistent filtration helps extend machine life and maintain accuracy. - Airborne contaminants exceed acceptable levels during multi-station grinding workflows

Facilities in the Philippines require controlled airflow to meet occupational safety expectations.

Engineered Dust Collection Solutions for Grinding Facilities

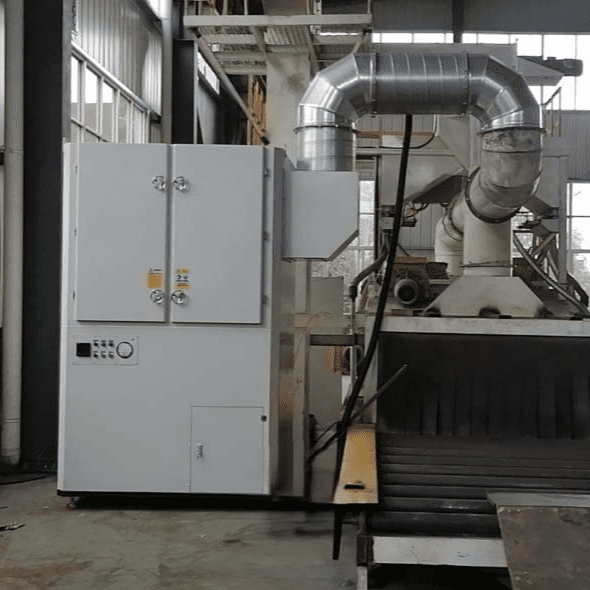

💠 High-Static Grinding Dust Extraction System

Industrial Dust Collector DJS1100/DJS1500

Built for heavy grinding environments requiring strong suction and stable airflow, this high-power system provides variable frequency control, massive HEPA filter area, and superior dust separation—ideal for continuous grinding production lines.

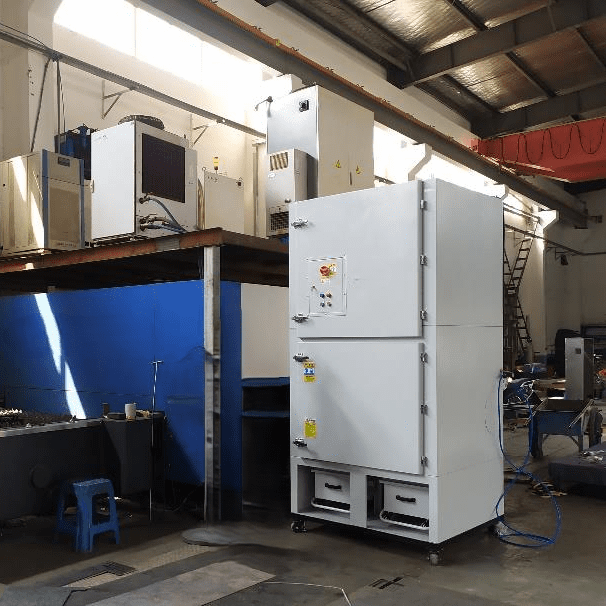

💠 Precision Grinding Booth Dust Control Unit

Industrial Dust Collector DJS550/DJS750

Featuring flame-retardant PTFE-membrane HEPA filters, dual dustbins, and a wear-plate inlet design, this system protects filters from abrasive impact while maintaining steady dust removal during prolonged grinding sessions.

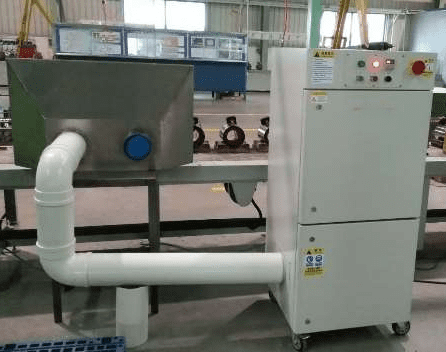

💠 Compact Grinding Bench Dust Collector

Industrial Dust Collector AJS220

A dependable, compact unit designed for grinders, polishers, carving stations, and tool-sharpening areas. Easy filter replacement, strong airflow, and low noise make it perfect for smaller workstations.

Where These Solutions Add Value in Grinding Operations

- Metal fabrication shops

- CNC machining centers

- Tool & die workshops

- Automotive machine shops

- Stainless steel finishing lines

- Furniture and hardware manufacturing

- Welding preparation and post-grind cleanup areas

Quick Comparison Table

| Solution | Key Benefit | Usage Area |

|---|---|---|

| High-Static Grinding Dust Extraction System | High airflow + constant pressure for heavy grinding lines | Metal fabrication & machining halls |

| Precision Grinding Booth Dust Control Unit | Flame-retardant HEPA filtration with dust-impact protection | Grinding booths, polishing stations |

| Compact Grinding Bench Dust Collector | Space-saving, efficient localized dust removal | Small workshops, tool-grinding benches |

| PTFE Membrane HEPA Filtration System | Captures 0.1–0.3µm fine metallic dust | High-precision grinding zones |

| Automatic Pulse-Jet Cleaning System | Ensures filter longevity during continuous operation | All grinding applications |

Cleaner, Safer, More Efficient Grinding

Grinding generates hazardous fine particulates that traditional ventilation cannot handle. NuPon’s certified industrial systems ensure:

- cleaner air

- better visibility

- extended equipment life

- reduced fire hazards

- safer operator breathing zones

As one of the Philippines’ rising leaders in engineered dust solutions, NuPon Technology Phils. Corp. empowers facilities to achieve superior grinding performance while meeting air-quality expectations with confidence.

Optimize Your Grinding Facility with NuPon Dust Solutions

Whether you operate a full-scale machining line or multiple grinding benches, our engineered dust collectors deliver unmatched reliability and filtration strength.