In blasting operations—whether sandblasting, grit blasting, or shot blasting—the air quickly fills with abrasive particulates, micro-metal fragments, silica-laden dust, and high-velocity contaminants. These airborne hazards not only degrade equipment and product quality but also pose severe risks to worker safety and facility compliance.

To maintain a high-performance blasting workflow, facilities must deploy engineered dust extraction systems capable of capturing heavy particulate loads, stabilizing airflow, and protecting operators from continuous dust exposure.

NuPon delivers certified industrial dust collection systems designed to withstand the harshest blasting environments—keeping visibility clear, air quality controlled, and production efficiency at its peak.

Practical Scenarios Where This Solution Becomes Essential

- Abrasive dust concentrations rise sharply during continuous blasting cycles

Facilities require stable extraction to keep airborne particulates at safe levels in Philippine blasting operations. - Heavy particulates begin affecting visibility and surface preparation quality

Overspray and blast media residues must be controlled to maintain consistent coating and finishing results. - Equipment wear increases due to abrasive dust infiltration

Strong filtration prevents intrusive particles from damaging machinery and reducing operational uptime.

Engineered Solutions for Blasting Facilities

💠 High-Volume Abrasive Dust Extraction System

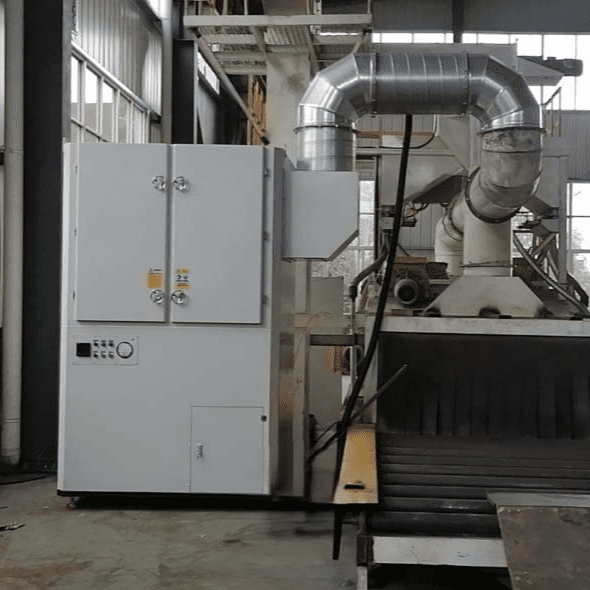

Industrial Dust Collector DJS1100/DJS1500

Built for massive particulate loads, this system uses variable frequency control, constant-pressure operation, and large HEPA filter arrays to capture blasting dust at the source—even under continuous heavy-duty use.

💠 Multi-Stage Blasting Booth Dust Containment Unit

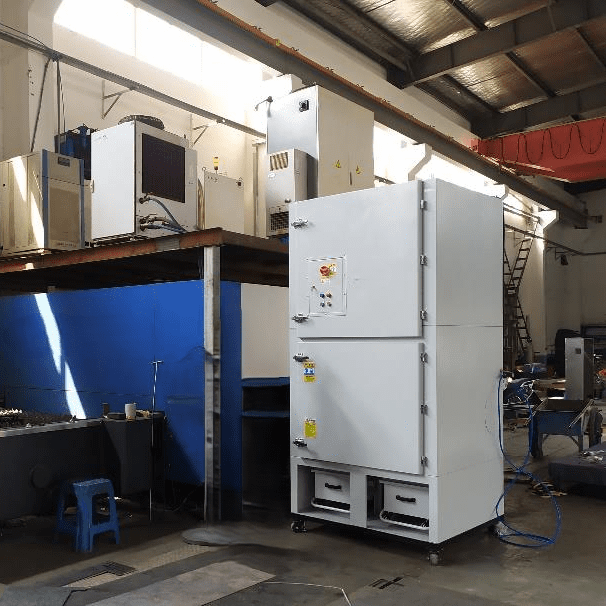

Industrial Dust Collector DJS550/DJS750

Equipped with flame-retardant PTFE membrane filters, dual dustbins, and high static pressure, this solution supports mid-size blasting booths, metal finishing lines, and abrasive cleaning stations.

💠 Compact Blasting Workstation Dust Collector

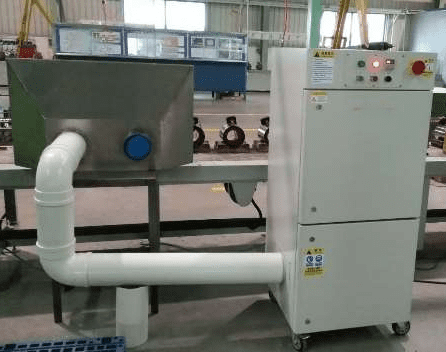

Industrial Dust Collector AJS220

A powerful yet space-saving solution for smaller blasting benches or precision blasting applications such as carving, polishing, and surface preparation. Features easy-to-service HEPA cartridge filters and a large-capacity bin.

Where These Solutions Add Value in Blasting Operations

- Sandblasting / Shotblasting Booths

- Steel Fabrication Yards

- Shipbuilding & Repair Facilities

- Automotive Restoration Shops

- Abrasive Surface Preparation Lines

- Casting & Foundry Cleaning Zones

Quick Comparison Table

| Solution | Key Benefit | Usage Area |

|---|---|---|

| High-Volume Abrasive Dust Extraction System | Maintains constant airflow for large blasting chambers; superior filter lifespan | Heavy blasting rooms, steel fabrication halls |

| Multi-Stage Blasting Booth Dust Containment Unit | Flame-retardant filters + dual dustbin for high particulate loads | Medium blasting booths, abrasive cleaning lines |

| Compact Blasting Workstation Dust Collector | Efficient localized capture for fine abrasive dust | Small blasting stations, carving/polishing benches |

| PTFE Membrane HEPA Filtration System | Captures 0.1–0.3µm dust for clean air compliance | Blasting rooms requiring high air purity |

| Automatic Pulse-Jet Cleaning System | Keeps filters clean during continuous blasting cycles | All blasting workflows |

Stronger, Cleaner, Safer Blasting Performance

Blasting environments demand rugged, high-efficiency dust control. NuPon’s engineered systems provide the airflow stability, filtration precision, and structural durability required to keep abrasive operations running safely and continuously.

With certified HEPA filtration, automatic pulse-jet cleaning, and high-static pressure fans, our solutions protect your workforce, extend equipment life, and help maintain compliance with industrial air quality standards.

Upgrade Your Blasting Facility with Philippine-Engineered Excellence

As a trusted industrial solutions provider in the Philippines, NuPon empowers blasting facilities with robust systems that exceed performance expectations.